| Model No | Garden / Landscape type – GT25213070 |

| Yarn Material | Monofilament P.E + Yellow Curly PP |

| Pile height | 25 mm |

| Stitches | 130/m |

| Density | 13650/sqm |

| Dtex | 7000 |

| Gauge | 3/8” |

| Backing | PP+NET+SBR, 4 tones |

| Size per Roll | 6’-6” x 82’-0” |

၎

င

၎

၎

| Model No | Football ( Fusal – Infilled type ) GT50416588CL-101 + 102L |

| Colour | Dark Green / Apple Green / White |

| Yarn Material | Monofilament P.E, Spine Shape |

| Pile height | 50 mm |

| Stitches | 165/m |

| Density | 10395/sqm |

| Dtex | 8800 |

| Gauge | 5/8” |

| Backing | PP Woven +NET+SBR, 2 tones |

| Size per Roll | 6’-6” x 66’-0” |

၎

င

၎

၎

| Model No | Children Sport type – GT25221098 |

| Yarn Material | Monofilament P.E + Green Curly PP |

| Pile height | 25 mm |

| Stitches | 210/m |

| Density | 22050/sqm |

| Dtex | 9800 |

| Gauge | 3/8” |

| Backing | PP+NET+SBR,4 tones |

| Size per Roll | 6’-6” x 66’-0” |

Installation & Maintenance

၎

င

၎

၎

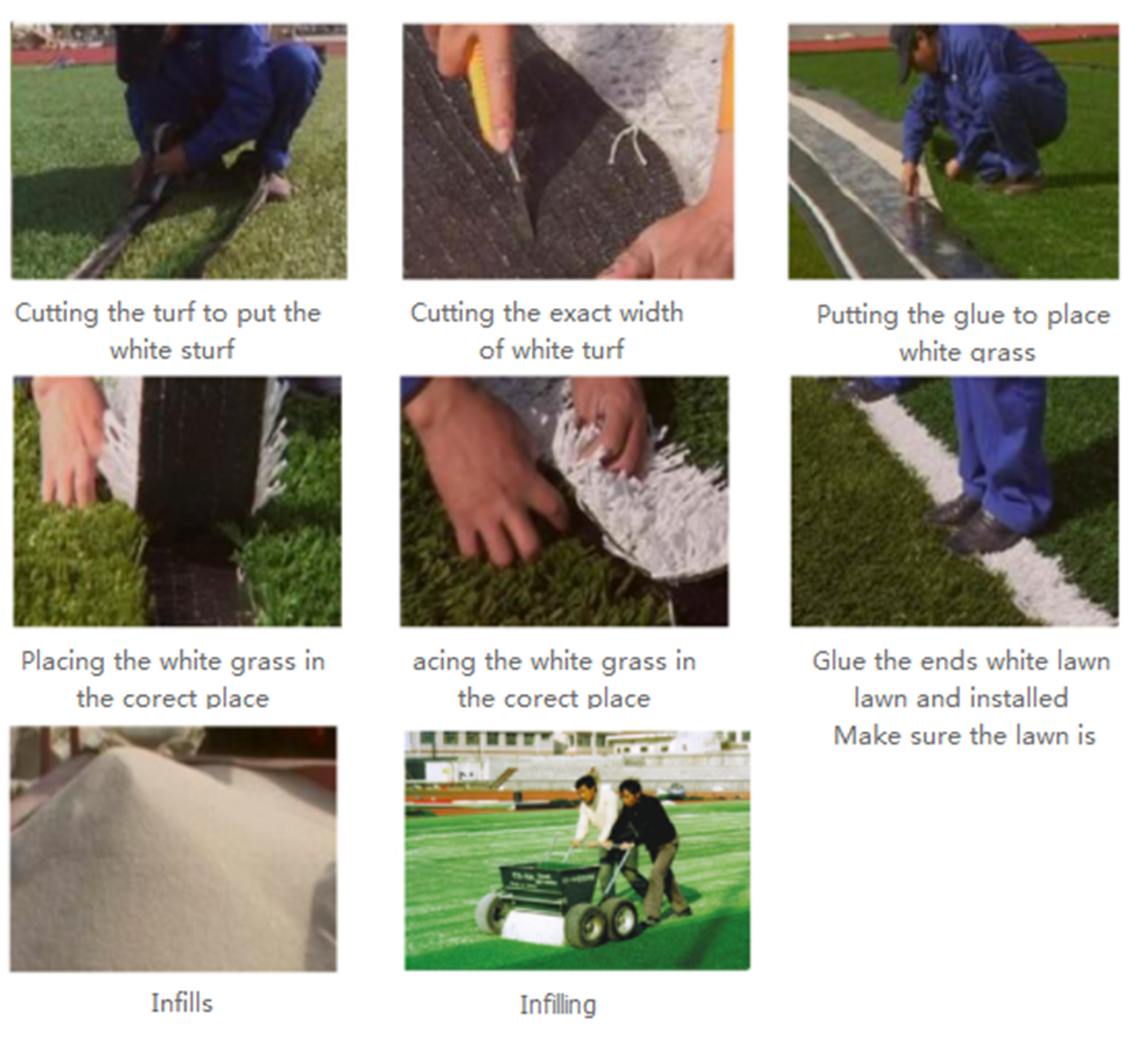

Installation Guidance of Artificial Turf for Football Field

(1) Construction preparation work

Site foundation plays an important role in artificial turf site. The smoothness, stability and drainage of site foundation will affect the use effect of artificial turf site. Therefore, before the formal paving of lawn, the following construction preparation work should be done well.

(1) The foundation is usually made of cement concrete, asphalt concrete or cement powder layer, sand gravel layer and so on, which has certain strength and stability;

(2) The foundation cannot produce cracks and freezing;

(3) For the flatness of the foundation, 3 meters straightedge error is less than 6mm; the site must have a certain slope to meet the requirements of site drainage;

(4) The foundation surface should be kept clean and dry, and the cement concrete foundation should be maintained for about 28 days after the completion of the concrete foundation, so as to ensure the

sufficient bonding strength of the base layer.

(2) Measure

In order to ensure the quality and smoothness of artificial grass paving, and ensure the quality and

perception of artificial grass, the artificial grass paving procedure is as follows:

Find the center point of the site and the two semi-circle, and according to the three point positioning ruler line, set the venue line and sideline intersection, and then set the exact position of field angle, point and line to the Pythagorean theorem, and then set the function point, line position, and use ink or paint line up.

(1) Find the center point of the site and the two semi-circle;

(2) According to the above three point positioning ruler line, set the venue line and sideline intersection;

(3) Set the exact position of field angle, point and line, according to the Pythagorean theorem and then set the function point, line position by using ink or paint.

(3) Pavement of football field

(1) The lawn glue must be stored in a cool room; quartz sand and rubber particles can be stored in the open air, but the quartz sand need to prevent rain;

(2) According to the pavement design plan of artificial lawn, paving personnel should pave the lawn one day ahead of schedule, so that the lawn naturally extends to the factory size, which can avoid the lawn joint cracking or protruding due to the lawn deformation and expansion after the completion of the

pavement;

(3) In order to ensure the pavement effect, the direction of the grass fiber should be consistent;

(4) After the lawn is unfolded, the white functional line outside the lawn should be cut down and put aside before the formal paving;

(5) In the process of artificial lawn paving, 2cm~3cm should be overlapped between the lawn of each roll, so as to make the adjacent lawn overlap as closely as possible;

(6) Spread the 20cm~30cm wide belt along the lawn joint, put it under the lawn, and try to make the lawn joint in the central part of the connecting belt; then daub the lawn glue evenly with the scraper on the connecting belt and the lawn which need to bind; not repeated gluing, otherwise there will be

foaming phenomenon; when the glue produces adhesive force (usually 10 to 30 minutes after the glue, and hands touch nonstick is appropriate), cohere the lawn on both sides, and beat with a rubber hammer to make sure the combination of bond; one-time cement is required, and cannot move back and forth the adhered lawn.

(7) To ensure the bonding effect of two volumes of adjacent lawn, the adhesive shall form spot bonding between the joint and the base. Point bonding can not only save the glue, but also the suspension state of lawn is advantageous to drainage and releasing the displacement caused by thermal expansion and contraction in use; the artificial lawn and the base layer can be fixed with glue directly, and the

connecting belt is not necessary;

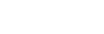

(8) After the basic splicing of the lawn, set each function line, point of the venue again; cut with a paper knife, then select the grass from a lot, put it in the jointing strip, scraping glue, put white grass back, bond and press with a rubber hammer, thus combining bond; it is difficult to draw arcs in narrow areas such as corner kicks. White lines can be cut into small pieces and spliced together;

(9)The construction of the environment temperature is over 5 DEG C; turf construction should

immediately stop work if encountered rain, snow and stormy weather, use tarpaulins to shelter the lawn, and ensure glue can be cured and the site is clean;

(10) After all the lawn has been bonded, begin to comb the lawn with the grass brushing machine;

(11) The curing time of the glue is usually three days, and the final strength is detected on the ten day. During curing, attention should be paid to the maintenance, avoiding exposure, immersion and

movement, so as to achieve the best bonding state.

(4) Laying of quartz sand and elastic particles

(1) The lawn is completely paved, and after acceptance, lawn filling is started;

(2) The scouring and cleaning of the heavy rain will cause a small loss of the filler. The place to be filled can be sprinkled with quartz sand and rubber particles which are completely swept into the turf.

(5) Prohibitions

(1) Smoking, setting off firecrackers and welding are prohibited on the lawn;

(2) Quartz sand should be dry, clean and free from dust, and the filling amount of quartz sand is 25-28 kg / square meters; the sand filling of the whole site should be divided many times and sand filling should be uniform; it must be combed repeatedly with professional carding equipment from outside to inside, so that quartz sand can be filled to the root of the grass silk according to the requirements, and filled with dense to ensure that the grass silk is not buried by sand;

(3) After the pavement of the quartz sand, the comb machine should be used to comb all the grass

vertically and horizontally once, then the elastic particles can be laid;

(4) Laying of elastic particles is 6-8 kg / square meters, paving speed and pavement quantity should be uniform from outside to inside; after laying, it is necessary to check the smoothness and quantity of the elastic particles, and the insufficient places need to be filled according to the amount;

(5) After the filling of quartz sand and rubber particles, rubber particles are required to be about 15mm less than that of the straw;

(6) After the filling is completed, the lawn is combed vertically and horizontally with the combing

machine, so as to ensure that all the grass wires are combed.

(6) Acceptance of artificial lawn pavement

(1) Appearance

i.Artificial turf colors are uniform without color difference;

ii.The markings colors and sizes of various functional lines and dot lines should comply with the requirements of FIFA rules, and the error is not more than 2 centimeters;

iii.There is no obvious gap between the two lawn joints, and the bonding is compact;

iv.The surface of the filled sand and colloidal particles is clean and the filling is full, and the error range of the flatness of the site is not more than 1cm of the 3M ruler;

v.No phenomenon, such as arching, cracking or degumming, is allowed to occur on the ground.

(2) Thickness of excipients and fillers Artificial grass with grass height of 50mm needs the following accessories:

| Excipients category | Specifications(mm) | Height (mm) | Application amount(kg/m2)

|

| Quartz sand | 0.2-0.8 | 20-30 | 25-28 |

| Rubber particles | 0.8-2 | 8-12 | 6-8 |

| Glue | Special adhesive glue for lawn | / | 0.12-0.15 |

| Black Band | 200-300 ( the width ) | / | According to site conditions |

| Remark | The thickness of filled quartz sand and rubber particles is determined according to the height of the lawn, and the rubber particles are about 10-15mm lower than the straw. | ||

၎

င

၎

၎

၎

င

၎

၎

၎

င

၎

၎

၎

င

၎

၎